How does ZheJiang MingDing Glass Technology Co., Ltd. use its industry experience to innovate and optimize the production process of Wired Laminated Glass?

1. Technological innovation leads industrial upgrading

ZheJiang MingDing Glass Technology Co., Ltd. is well aware of the key role of technological innovation in improving product competitiveness. The company has invested a lot of resources in the construction of the R&D team and has absorbed a group of experts and technicians with profound theoretical knowledge and rich practical experience in the field of glass processing. These talents are not only proficient in traditional glass processing technology, but also keep up with the international technological frontier and constantly explore the application of new materials and new processes. In the production of Wired Laminated Glass, the company has independently developed a number of patented technologies, such as fine wire technology and efficient interlayer composite technology, which effectively improves the safety, light transmittance and aesthetics of the product.

2. Process optimization improves production efficiency

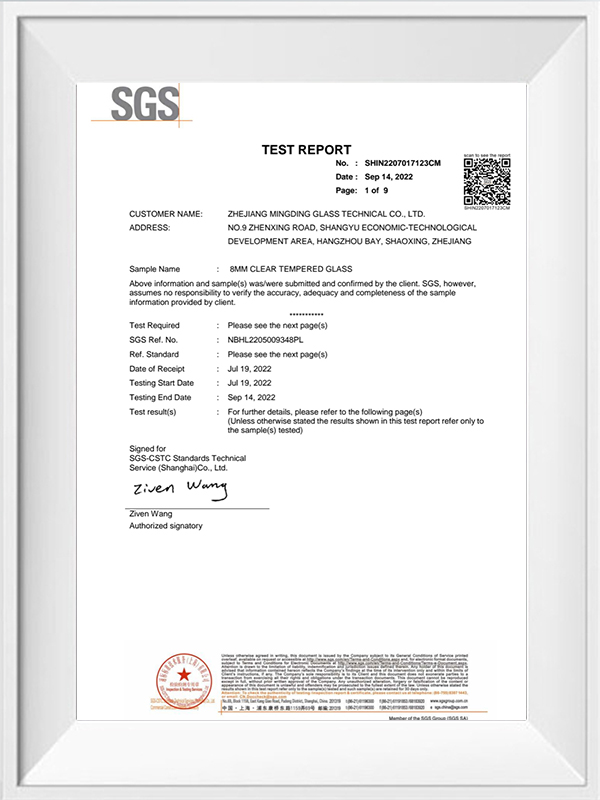

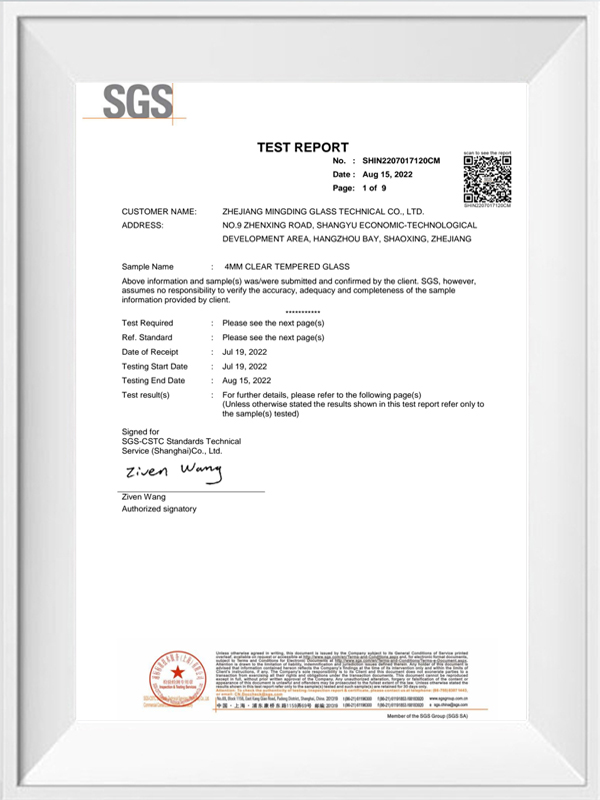

In terms of process optimization, ZheJiang MingDing Glass Technology Co., Ltd. has made full use of more than 17 years of industry experience to comprehensively sort out and refine the production process of Wired Laminated Glass. By introducing advanced automated production lines and intelligent control systems, the whole process of automated operation from raw material cutting, cleaning, wire clamping, interlayer compounding to finished product inspection has been realized. This not only greatly improves production efficiency and reduces labor costs, but also significantly improves product consistency and stability. At the same time, the company has also established a strict quality management system to strictly monitor every link to ensure that every piece of Wired Laminated Glass can meet the highest standards.

3. Customized services meet diversified needs

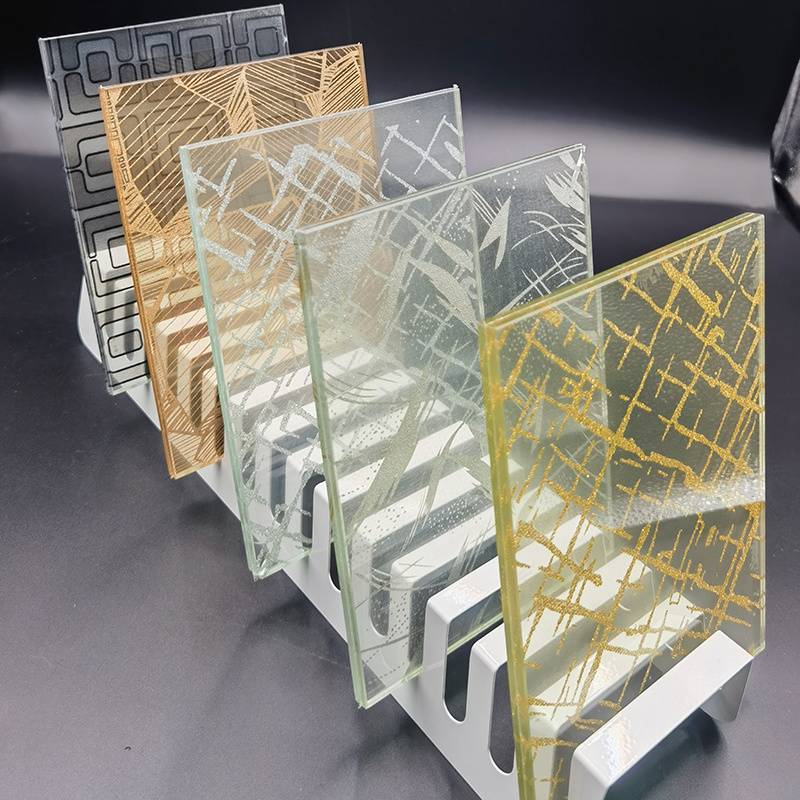

With the diversified development of the market, customers' demand for glass products is becoming increasingly diversified. The company makes full use of its industry experience, deeply understands the special needs of Wired Laminated Glass in different industries and different application scenarios, and provides personalized customized services. Whether it is building curtain walls, interior partitions, security doors and windows or artistic decoration, the company can tailor glass products that meet safety regulations and have unique aesthetics according to the specific needs of customers. This customized service model not only enhances the company's market competitiveness, but also brings customers a more satisfactory use experience.

4. Environmental protection concepts are integrated into the entire production process

While pursuing technological innovation and process optimization, the company also actively responds to national environmental protection policies and integrates green production concepts into the entire production process of Wired Laminated Glass. The company uses environmentally friendly raw materials and clean energy for production, reducing pollution and damage to the environment. At the same time, by optimizing the production process, improving resource utilization and waste recycling rates, a win-win situation of economic benefits and environmental protection has been achieved. This responsible environmental protection attitude has not only won the trust of customers and the praise of the society, but also laid a solid foundation for the sustainable development of the company.

ZheJiang MingDing Glass Technology Co., Ltd. has made remarkable achievements in the production of Wired Laminated Glass with its profound industry experience, continuous technological innovation, refined process optimization, personalized customized services and green and environmentally friendly production concepts. In the future, the company will continue to uphold the principle of "quality first, customer first", constantly pursue excellent quality and service levels, and provide global customers with more high-quality, safe and environmentally friendly glass products.

ore

ore

ore

ore

ore

ore

ore

ore

中文简体

中文简体