Tempered glass has become an indispensable material in modern architecture and industrial manufacturing. With its excellent mechanical properties and safety characteristics, tempered glass is not only widely used in building curtain walls, interior partitions, and automobile windshields, but also demonstrates its unique value in home furnishings, electronic devices, and high-end industrial applications.

Basic Concepts and Characteristics of Tempered Glass

Tempered glass is a type of safety glass that undergoes special heat or chemical treatments. Its core features are high strength and excellent impact resistance. Compared to ordinary glass, tempered glass breaks in a safer manner when subjected to stress. Once broken, it forms small, particle-like fragments rather than sharp shards, significantly reducing the risk of injury. This safety factor has led to its widespread use in public places, transportation, and high-rise buildings.

Tempered glass has strong thermal shock resistance, allowing it to withstand sudden temperature changes without breaking. This property makes it crucial for kitchen protection, high-temperature equipment, and solar panels. Furthermore, tempered glass exhibits stable optical properties and is less susceptible to deformation or distortion, ensuring clear and realistic visuals.

Tempered Glass Manufacturing Process

The manufacturing process of tempered glass is the core guarantee of its performance. It mainly includes thermal tempering and chemical tempering. Thermal tempering heats ordinary glass to a high temperature near its softening point and then rapidly air cools it. This creates a compressive stress layer on the surface while maintaining a tensile stress layer within the glass. This unique distribution of internal and external stresses greatly enhances the glass's bending strength and impact resistance, and also determines its safety in the event of breakage.

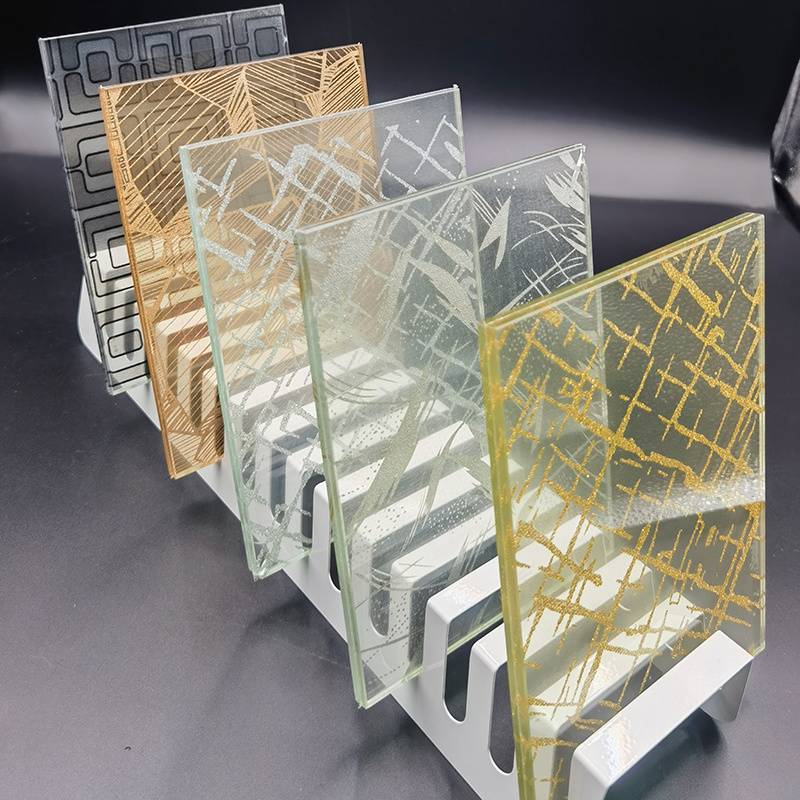

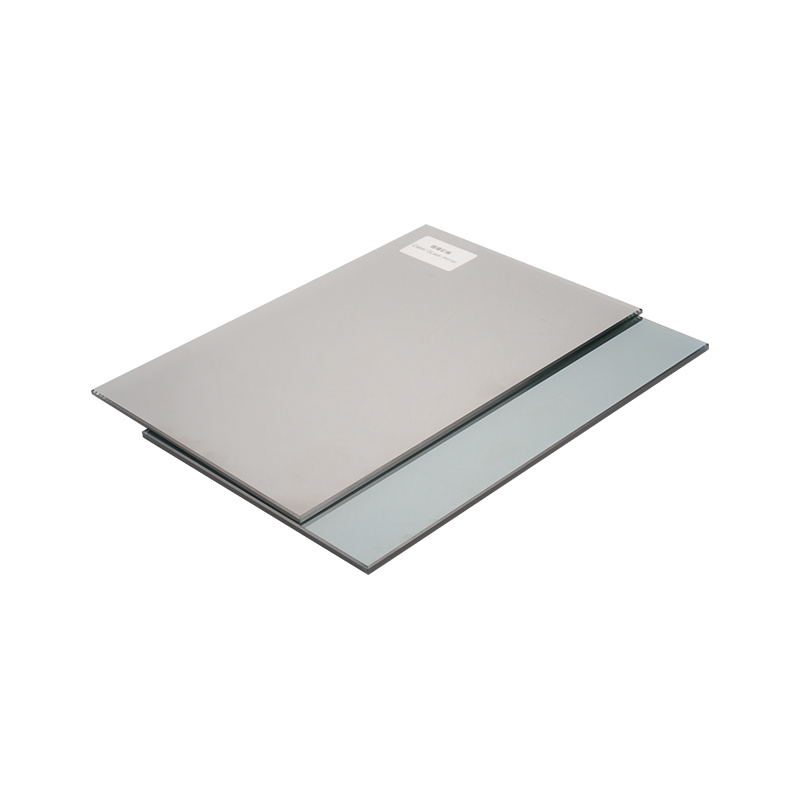

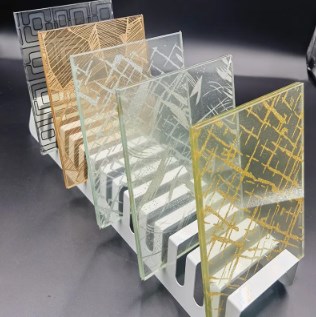

Chemical tempering uses the principle of ion exchange to replace small ions on the glass's surface with larger ions, thereby creating compressive stress on the surface. Compared to thermal tempering, chemical tempering can achieve high strength on thinner glass materials while also providing better scratch resistance and optical stability. Both processes have their advantages, and choosing the right one based on the specific application scenario can achieve the optimal balance between performance and aesthetics.

The Mechanical and Safety Properties of Tempered Glass

The mechanical properties of tempered glass are one of its core advantages. Tempered glass is typically several times stronger than ordinary annealed glass, allowing it to withstand large static loads and effectively resist accidental impacts. Its breakage pattern is also a key indicator of safety. Upon shattering, it forms granular fragments, preventing sharp scratches and meeting modern building and traffic safety standards.

Tempered glass offers high wind pressure and explosion resistance, making it an excellent choice for high-rise building curtain walls, subway platform partitions, and security barriers in large shopping malls. Its impact resistance and safe breakage characteristics make it an indispensable material choice in architectural design, while also meeting the requirements of modern urban safety management.

Applications of Tempered Glass in Architecture

In the architectural field, tempered glass is widely used in structures such as curtain walls, skylights, sunrooms, and interior partitions. Its high strength and transparency enable architects to realize bolder design concepts while ensuring structural safety and visual clarity. Tempered glass can be combined with materials such as laminated glass and Low-E glass to achieve thermal insulation, sound insulation, and UV protection, enhancing the overall performance and comfort of a building.

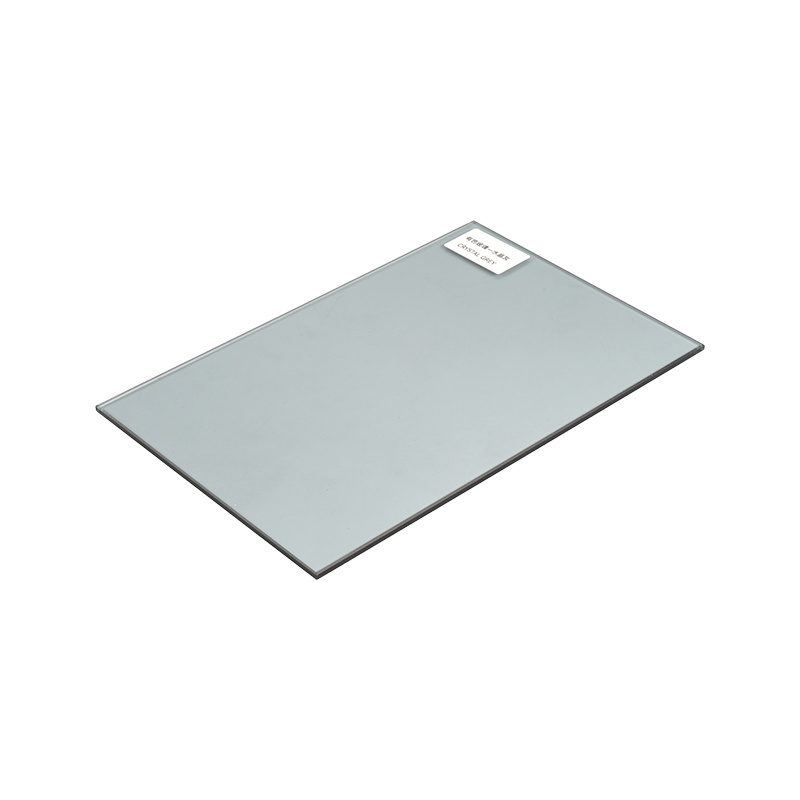

In modern urban architecture, the use of tempered glass extends beyond functionality; its decorative properties are also fully utilized. Through surface coating, tempering, and pattern design, tempered glass can meet diverse aesthetic needs, achieving an ideal balance between safety and aesthetics in buildings.

Applications of Tempered Glass in the Automotive and Transportation Sector

In the automotive industry, tempered glass is primarily used for side windows and rear windshields, where its high strength and safety effectively enhance occupant protection. Tempered glass's impact and heat resistance ensure excellent vehicle safety at high speeds and in the event of an accidental collision. Furthermore, its lightweight nature helps reduce vehicle weight, improving fuel efficiency and power performance.

In public transportation, tempered glass is widely used in station waiting areas, guardrails, and partition walls. Its safety and durability ensure the safety of people in public environments. Furthermore, its light transmittance ensures a bright and open space, enhancing user experience and visual comfort.

Thanks to its high strength, safety, and versatility, tempered glass has become a vital material in modern architecture, transportation, industry, and the home. The continuous optimization of its manufacturing process, the continuous improvement of its mechanical properties and the trend of intelligent development give tempered glass broad prospects in future applications.

中文简体

中文简体