In modern architecture and industry, one material has become indispensable due to its unique properties: tempered glass. This specially treated glass retains the inherent transparency of glass while boasting strength and safety far exceeding that of ordinary glass, playing a crucial role in numerous applications.

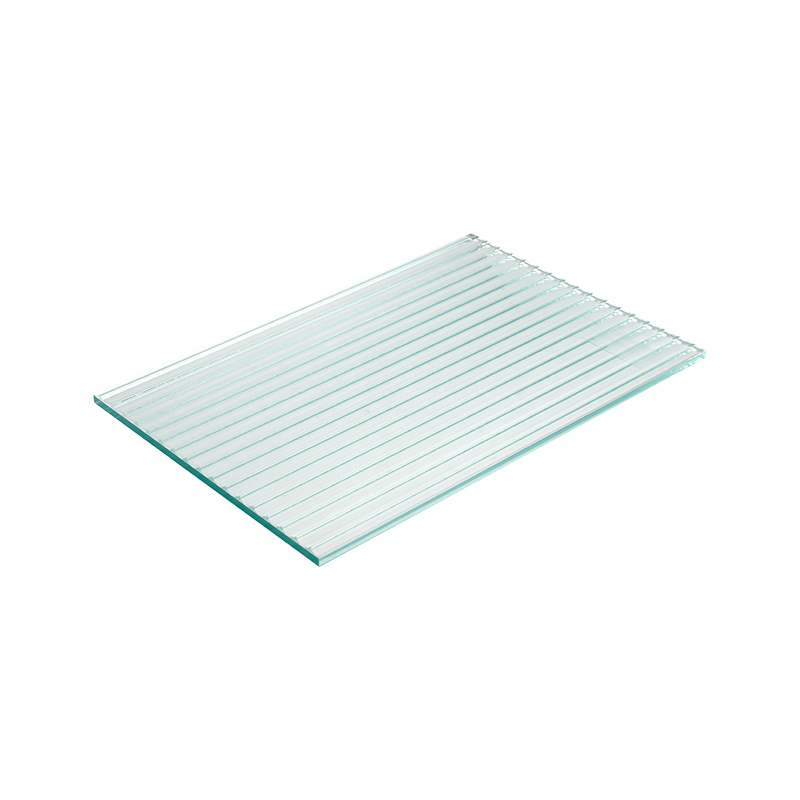

The most striking feature of tempered glass is its exceptional mechanical properties. Compared to ordinary glass, its impact resistance has been significantly improved due to its unique internal stress structure. During processing, the glass undergoes high-temperature tempering and rapid cooling, resulting in compressive stress on the surface and tensile stress within. This stress balance allows it to more effectively dissipate energy when subjected to external forces, reducing the likelihood of breakage.

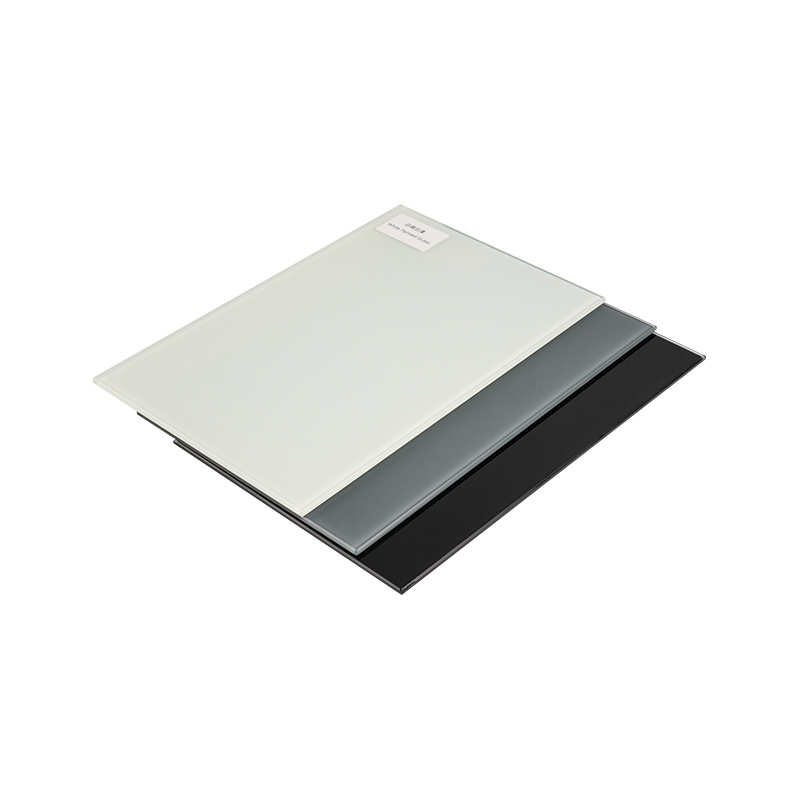

In addition to its high strength, tempered glass also offers significant safety advantages. When shattered by extreme forces, it does not form large, sharp fragments like ordinary glass, but instead shatters into countless fine, non-sharp particles, significantly reducing the risk of injury. This characteristic makes it highly sought after in safety-critical environments.

Tempered glass also boasts excellent thermal stability. It's less susceptible to cracking due to thermal expansion and contraction within a wide temperature range, making it adaptable to temperature fluctuations in diverse environments and expanding its application scenarios.

The Secret of Tempered Glass Production: The Conflict Between High Temperature and Stress

Tempered glass isn't created overnight; it undergoes a series of sophisticated processes. The core of its production lies in "tempering," a process that essentially alters the molecular structure within the glass to enhance its performance.

The selection of raw materials is crucial. High-quality flat glass is the foundation of tempered glass production, ensuring it is free of visible impurities and bubbles to ensure the stability of the final product. Next, the glass is cut to the desired size and then edge-polished to remove sharp edges. This step is both for safety and to reduce breakage caused by stress concentration during subsequent processing.

The actual tempering process begins with high-temperature heating. The glass is fed into a furnace and uniformly heated at a specific temperature, bringing it close to its softening point. The key to this process lies in precise temperature control and uniform heating; even the slightest deviation can impact the quality of the final product. Once the glass reaches the desired temperature, it is rapidly fed into a cooling device where high-pressure cold air is used to uniformly and rapidly cool its surface.

This rapid cooling process causes the surface layer of the glass to rapidly shrink and solidify, while the interior remains relatively hot. This contraction during the subsequent cooling process creates strong compressive stress within the glass. This stress structure gives tempered glass its exceptional strength and toughness, significantly improving its performance.

Tempered Glass Applications: A Versatile Player in Multiple Fields

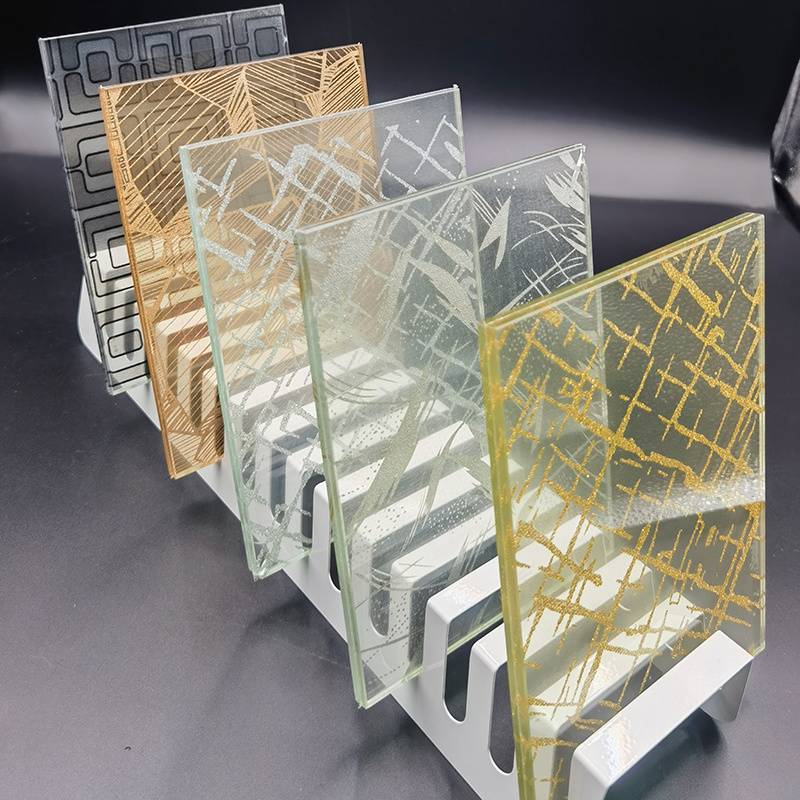

In the architectural field, tempered glass is a favorite in modern building design. It is widely used in curtain walls, skylights, and interior partitions. Curtain walls, with their high strength and transparency, meet the lighting needs of buildings while showcasing a simple, modern aesthetic, becoming a common feature of urban landmarks. Skylights, with their excellent heat and impact resistance, provide ample natural light while protecting the interior from external wind and rain. The automotive industry is also a key application area for tempered glass. Car windshields typically use laminated tempered glass. When shattered by impact, the fragments adhere to the laminated glass, protecting the occupants. Side and rear windows are often made of standard tempered glass, ensuring sufficient strength while also allowing for easy escape in an emergency, ensuring both safety and practicality.

Tempered glass is also ubiquitous in the home. Tempered glass tabletops and coffee tables, with their smooth surface and wear resistance, are popular choices for home decor, offering both aesthetics and practicality. Shower doors are particularly reliant on tempered glass, as its impact resistance and safety after shattering effectively prevent accidental injuries during bathing.

As a material that combines performance and aesthetics, the development of tempered glass has witnessed the advancement of materials science. From continuous optimization of production processes to the continued expansion of applications, to innovative future technologies, tempered glass, with its unique appeal, is playing an increasingly important role in modern society, bringing greater convenience and safety to people's lives and work.

中文简体

中文简体